You can become a leader in construction management by completing a certificate program in construction management. Its cutting-edge curriculum provides students with a variety of essential skills that are vital in today's fast-paced industry. Learn about BIM, construction scheduling, green building and other topics. The program will help them develop leadership and interpersonal skills. A construction management certificate is the best way of getting started in your career, no matter if you want to start your business or work in construction.

Coursework

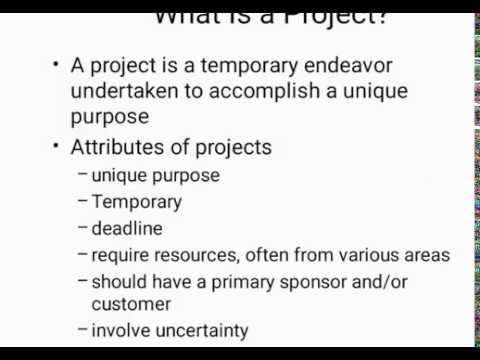

The course for a certificate in construction management is designed to help construction project managers improve their skills. This course covers topics including project planning and scheduling, budgeting as well as manpower allocation and code compliance. In addition, the course covers topics such as the critical path method and scheduling tools. The student will also learn about the importance of Cash Flow Diagrams. This course is necessary if one wants to work in construction.

A student must complete all coursework within the four-year period of admission to earn a certificate in construction management at the University of Michigan. The average student must earn a C or have an overall GPA of at least 2. The certificate is awarded simultaneously with an undergraduate degree. This program is for those with experience in construction. However, applicants must be admitted to this program as soon possible.

Credentials

A construction management certificate is a valuable credential to have for a job in the construction industry. Having this certification shows potential employers that you are serious about your future in this field. This certification is a professional advantage for those looking to start a business or work as a freelancer in this field. Different colleges and universities can offer credentials for construction management certificates. Construction is always changing, and those who have the right skills are highly sought-after.

Construction certifications are beneficial to all involved in the construction process. These programs are beneficial for all involved in the construction process. They show that a worker has a high level of skill and is knowledgeable about the construction industry. Earning this certification can help you get more for your services. Many cities across the country are hiring people in the construction field and a construction certification is an excellent way to stand out from the competition.

Requirements

While a certificate in construction management does not guarantee employment, it can help you improve your job prospects. Students who complete a certificate program typically gain knowledge in building information modeling, project delivery, and decision-making. Certificate programs typically last two years, and require no additional coursework. It will help you grow your career by proving your expertise in the field. You don't have to be an expert in your field to receive a certificate.

You can also get an exam-style certificate. This type of certificate is available for between $500 to $1,100. You will need to pass a final examination. Once you pass the exam, the certificate will be yours. Be sure to budget for it. The requirements for earning a certification will vary depending on the level of your education and your employer's requirements. You should learn as much as you can about each option before making a decision to pursue one.

Online programs

It is possible to earn a certificate in construction management online. This will allow you to be more competitive than other job candidates. This certificate shows employers that you're capable of taking on high-level roles in construction companies. Ashworth College offers a range of online courses for construction management certificates at very affordable tuition rates. Click the links below for more information about this program. We hope that this information is useful to you. The construction industry is highly competitive, so earning your construction management certificate online will help you land that job.

The construction management certificate will allow you to supervise employees more effectively and coordinate projects better. This course covers the most recent topics in project management, scheduling and BIM, construction law and green building. The course also emphasizes leadership and interpersonal skills. This is a great option for those who want to break into the construction industry, but don't have the time or education to pursue an advanced degree.

FAQ

What is Kaizen?

Kaizen refers to a Japanese term that stands for "continuous improvements." It is a philosophy which encourages employees in continuously improving their work environment.

Kaizen is founded on the belief of everyone being able to do their job well.

What are the four main functions of management?

Management is responsible for planning, organizing, directing, and controlling people and resources. Management also involves setting goals and developing policies.

Management is the ability to direct, coordinate, control, motivate, supervise, train, and evaluate an organization's efforts towards achieving its goals.

These are the four major functions of management:

Planning – Planning involves deciding what needs to happen.

Organizing: Organizing refers to deciding how things should work.

Directing – This means to get people to follow directions.

Controlling: Controlling refers to making sure that people do what they are supposed to.

What are the most important management skills?

Managerial skills are crucial for every business owner, regardless of whether they run a small store in their locality or a large corporation. These skills include the ability of managing people, finances, time, space, and other factors.

When you need to manage people, set goals, lead teams, motivate them, solve problems, develop policies and procedures and manage change, management skills are essential.

As you can see there is no end to the number of managerial tasks.

What is TQM, exactly?

When manufacturing companies realized that price was not enough to compete, the industrial revolution brought about the quality movement. To remain competitive, they had to improve quality as well as efficiency.

Management realized the need to improve and created Total Quality Management, which focused on improving all aspects within an organization's performance. It included continuous improvement processes, employee involvement, and customer satisfaction.

How does Six Sigma work

Six Sigma uses statistical analysis for problems to be found, measured, analyzed root causes, corrected, and learned from.

First, identify the problem.

Next, data is collected and analyzed to identify trends and patterns.

The problem can then be fixed by taking corrective measures.

Finally, data will be reanalyzed to determine if there is an issue.

This continues until the problem has been solved.

Statistics

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

External Links

How To

How does Lean Manufacturing work?

Lean Manufacturing processes are used to reduce waste and improve efficiency through structured methods. These processes were created by Toyota Motor Corporation, Japan in the 1980s. The aim was to produce better quality products at lower costs. Lean manufacturing eliminates unnecessary steps and activities from a production process. It includes five main elements: pull systems (continuous improvement), continuous improvement (just-in-time), kaizen (5S), and continuous change (continuous changes). Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement is constantly improving upon existing processes. Just-in-time refers to when components and materials are delivered directly to the point where they are needed. Kaizen means continuous improvement. Kaizen involves making small changes and improving continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. These five elements are combined to give you the best possible results.

Lean Production System

Six key concepts are the basis of lean production:

-

Flow: The goal is to move material and information as close as possible from customers.

-

Value stream mapping- This allows you to break down each step of a process and create a flowchart detailing the entire process.

-

Five S's – Sort, Put In Order Shine, Standardize and Sustain

-

Kanban - use visual signals such as colored tape, stickers, or other visual cues to keep track of inventory;

-

Theory of constraints - identify bottlenecks in the process and eliminate them using lean tools like kanban boards;

-

Just-in-time delivery - Deliver components and materials right to your point of use.

-

Continuous improvement is making incremental improvements to your process, rather than trying to overhaul it all at once.